As well as being recognised nationwide for our reliable lift services, we also regularly donate to charity. When we are not working on your lift, you can find us donating to and supporting local charities. Our generous owners believe in donating and being part of the local community.

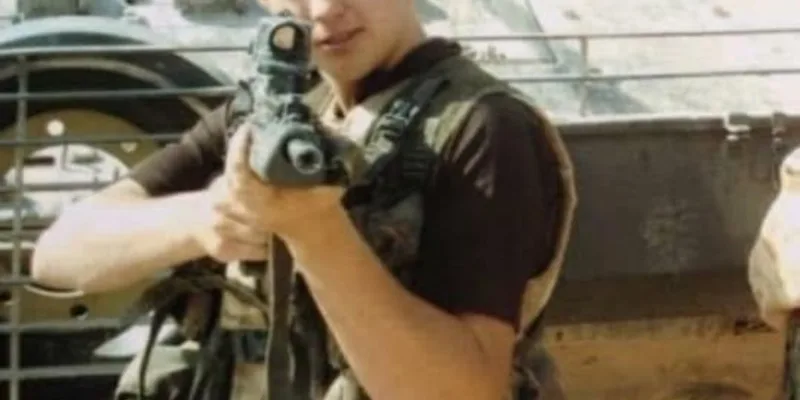

Recently, our charity donation portfolio was expanded. We donated to The Lee Rigby Foundation, an excellent charity supporting military families, veteran’s families and serving military families. They were enjoying a pleasant meal at Basmati, where it just so happened our owners were there too. It was amazing having a charity with a great cause so close to us.

Basmati is an Indian restaurant, located in the heart of Newcastle-under-Lyme. Ever since our humble beginnings, it has been our Managing Director’s number one place to eat out. He goes every week without fail and is well known there as a regular customer (and for eating mountains of food). Our lift modernisations and Basmatis curry have something in common, they will spice up your life.

In addition, we regularly support Aim Higher, a charity that supports families living with autism. Based in hull, they raise awareness for autism and regular host events to help those living with the condition. Our Managing Directors wife co-founded Aim Higher in 2016, ever since they have raised lots of money. Our charity donation portfolio is expansive and we intend to keep donating to charities.

Furthermore, we sponsor local Stoke-based charity Dougie Mac. They are a charity that supports families in need. We have done lots to help them and we will continue to.